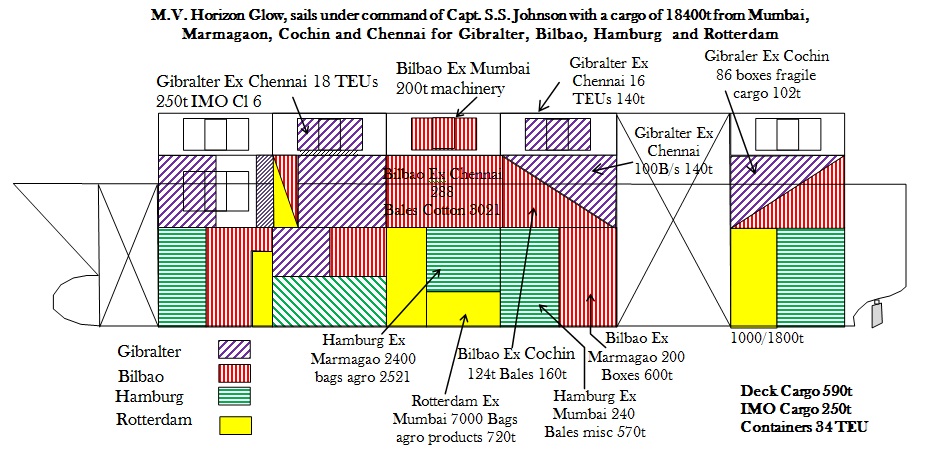

A ship’s cargo plan shows the distribution and other details such as load / discharge ports; the quantities of different parcels onboard; and information that will help stevedore, plan the discharge of cargo. Planning the stowage on a multipurpose cargo ship is very challenging. There can be several permutations of stow. A loading list is procured by the cargo division of shipping company, after a commitment has been made to load a certain quantity for a range of ports on say east and west coast of India. Port rotation of loading as well as discharging; the cubic volume of spaces available; load densities of different decks; dimensions of cargo units; any specialized cargo; any dangerous cargo; any heavy lift; if the cargo would be discharged by ship’s gear; dimensions of hatch square; etc are the variety of information must be available with the planner. The task of initial planning is seldom given to the ship’s officer. The cargo division of a shipping company or the agency would normally undertake this responsibility. In Ports like Antwerp, Bremen, Hamburg, etc plan is prepared ashore. Loading would probably start even before the lines are all fast. Though, the stevedore and agents are highly professional and would surely have expertise on exporting cargoes through ships, it is the responsibility of Master to ensure that no claims come up. The ultimate responsibility in respect of stowage, safety, securing, etc is the ship’s. Chief Officer must try and get the tentative plan as soon as possible and evaluate it from all the angles. He must also duly acknowledge the receipt including the date and time of receipt. In Capetown a tentative cargo plan for full load is given to

the Master right in the beginning. Before giving an ok, the plan must be checked for:

1. Stability at departure and intermediate passage.

2. SF / BM and sustainability of securing at departure and intermediate passage.

3. Port rotation.

4. Segregation.

5. Contamination and pilferage angle.

6. Load density.

7. Possibility of smooth discharge.

8. Legality of the loading and the location.

Chief Officer must complete the finished cargo plan with relevant stability calculation prior departure. Copies of the plan are made, before the vessel sails. The copies are forwarded to reach the agents at ports of discharge, to allow the booking and reservation of stevedore gangs, as appropriate.

Loading as well as securing must be planned. The objective of pre-planning provides commercially and professionally sound environment. It also aims towards safety of the personnel, ship and cargo, at all stages of carriage, and also during cargo operations.

The cargo plan should include relevant details of cargoes, i.e. total quantity, description of packages, bales, pallets, weights, ports of discharge, etc. The ports of discharge are normally ‘highlighted’ in specific colours, reducing the likelihood of a parcel of cargo being over carried to the next port. Giving different colours or shades to different ports of discharge helps visualizing the stow after the cargo of a certain port has been discharged. Cargo must appear safely securable causing no threat in respect of stability or stress. Safety during intermediate stages is very important on general cargo ships and parcel carriers.

Most plans normally have following details in addition to the one stated above:

- Name of the vessel and the Master under whose command she is.

- List of loading / discharging ports, in order of call.

- Sailing draughts.

- Hatch wise tonnage breakdown with colour key to identify discharge ports.

- Voyage number.

- Reference to the cargo manifest.

- Volume and location of empty space remaining.

- List of dangerous cargo and quantity, if any.

- List of special cargo, if any.

- Statement of deadweight, fuel, stores, water, etc.

- Any pre-slung cargo, deck cargo, IMO cargo, containers, etc.

- Chief Officer’s and Master’s signature.

The plan provides at a glance, the distribution of the cargo and shows possible access to it in the event of fire or the cargo shifting. It also helps the agents / stevedore to decide about booking of equipment, forklift, etc. port wise coloring helps to rule out any ‘over-carriage’ and the possibility of short delivery at the port of discharge.

General Precautions

All cargoes should be loaded having due regard to the order of discharge. The order of loading and the location should be planned accordingly.

- Cargo information, including gross weight of the cargo or cargo units and any special remarks detailed in the shipping documents, should be recorded and used in planning.

- Load density and space available must be checked carefully.

- Wherever practicable, where more than one port is involved for loading or unloading, the cargo should be loaded in layers rather than columns or walls. This is to avoid the development of high vertical walls of cargo. When high stow is not avoidable, it should be in forward underdeck or aft underdeck area with adequate depth and proper lashings. Walls of cargo should never exist in port and starboard wings.

- Care should be taken not to over stow heavy cargo over lighter cargoes. This may lead to a collapse of the stow and stability issue. Fragile cargo should not be overstowed with heavy cargoes. It will lead to the damage to the cargo underneath.

- Cargo should be stowed so as to allow accessibility to key areas, during the passage, as much as practicable.

- Deck cargo should be stowed in accordance with the Statutory Regulations; applicable cargo rules; special contracts; etc. Cargo should be kept clear of hatch coamings to allow safe access. Access to safety equipment, firefighting equipment (particularly fire hydrants) and sounding pipes should be ensured. Any obstruction in the access way such as lashings or securing points should be painted white to make them more easily visible.

7. An old thumb rule for allotting the quantities is 30% to 35% on tween decks and above and 65% to 70% in lower holds. Loading and stability manual, however must be duly used as reference.

8. Bilge wells must be ensured clear. Pumping out of bilges should be possible in loaded condition.

9. Proper and adequate dunnage must be used. Separation from metal parts; spreading weight of heavy cargoes; and lead towards the bilges; etc considered as appropriate.

10. Pilferable cargoes, sometimes, referred to as locker cargo must be protected from pilferage. Examples of this are shoes, clothing, spirits, grocery items and electrical goods. Anti-pilferage watch, tallying, etc being the usual precautions.

11. If there is any risk in handling, then the items should be clearly marked with the international symbols as shown above.

12. Useful information regarding various general cargoes is available in a publication called Thomas Stowage.

13. The most efficient use of space must be ensured.

14. Cargo planning must consider the stability, efficiency of securing and stresses, not only at departure first port but also for the intermediate stages also.

If cargo has to be loaded differently than what is provided in the loading manual, approvals from class must be obtained where in doubt as to the safety and legality.

The MS (Carriage of Cargoes) Regulations 1999 (SI 1999 / 336) (regulation 6) specifies that the owner and Master must ensure that:

- The cargo and cargo units carried on or under deck are loaded, stowed and secured so as to prevent as far as practicable, throughout the voyage, damage or hazard to the ship and the persons onboard and loss of cargo overboard.

- Appropriate precautions are taken during loading and transport of heavy cargoes or cargoes with abnormal physical dimensions. This is to ensure that no structural damage to the ship occurs and to maintain adequate stability throughout the voyage.

- Appropriate precautions are taken during loading and transport of cargo units onboard ro-ro ships, especially with regard to the securing arrangements onboard such ships and on the cargo units and with regard to the strength of the securing points and lashings.

- Cargo units must be secured in accordance with the Cargo Securing Manual.

Every cargo voyage is a fresh experience different from any text that is in the books. A cargo officer has to use all his imaginative faculties in addition to the cautionary guidance available. Though the general cargo ships have reduced in number but the unique charm about challenges of conventional cargo handling on these ships will always prevail.

(You may also visit my youtube videos @captsschaudhari.com)

Link: https://www.youtube.com/channel/UCYh54wYJs1URS9X5FBgpRaw/feature

Leave a Reply